A Quick Guide to Installing Your Own Artificial Turf

The advantages of artificial turf are many, especially in the wet muddy winters of Victoria. They are becoming an increasingly common landscaping feature here in town. Here is a quick guide on how to do this yourself.

Transport

First you will need to have either two people available, a pickup truck, and/or a carpet trolley to get it from the store onto your install site. As of this writing, none of the vendors in Victoria will deliver it to your front step.

The rolls are like big carpet rolls. They weigh up to 60 lbs per 100 square ft. For a 15 foot by 15 foot roll, you are looking at 100 lbs. It is best not to drag them on the ground as that can damage the artificial grass fibres. Due to their minimum width of 15 ft, they will not fit in your average sedan.

Base Prep

The base prep is pretty much the same as a paver base. You will want around 4 inches of compacted ¾” road base, which can be obtained from a local gravel or landscape yard. Most of these places will deliver for a fee. You will need a plate compactor, which can be rented as well for a day.

It is important that any old vegetation is removed as that can cause pockets and bumps. Additionally, ensure that sufficient dirt and vegetation is removed so that at the end of the day, the installed turf will be at the correct level and grade. Use a landscape rake to ensure that the base is as flat and smooth as possible.

Install

Once the base is ready, you take your giant roll of turf and roll it out onto the prepared surface, utilizing as little waste as possible. A knife will be required in many instances to cut it to the desired size and shape. 4” steel galvanized spikes are to be used along the edge of the turf to pin them down about every foot or so. A special silica sand like material is then spread on top to help keep the fibres up and the overall turf down. This can be obtained from your artificial turf supplier. Follow the instructions on the bag.

A hard push broom or a power broom will then need to be used to sweep up the fibres, which until now have been compressed during transport.

Joints

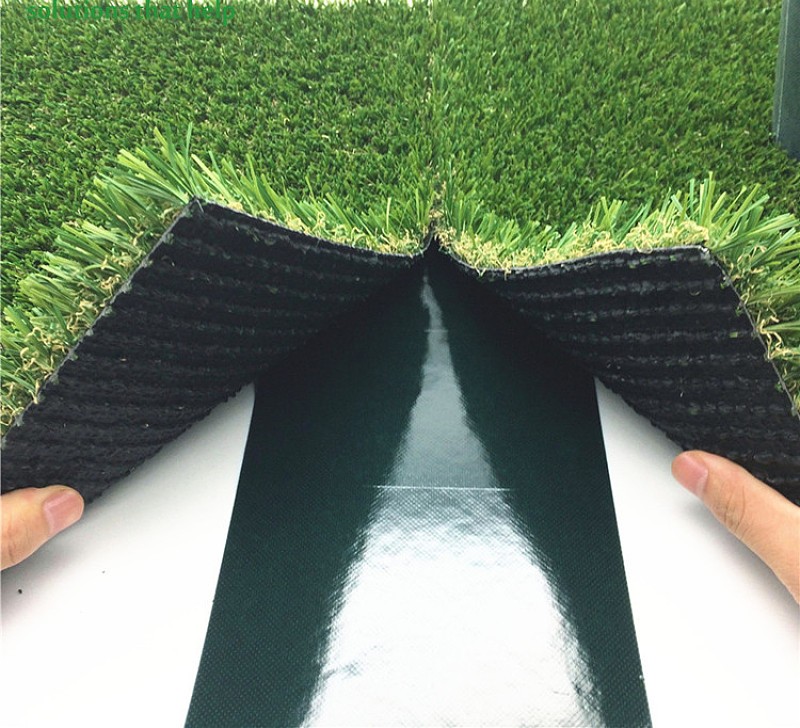

If two or more pieces need to be joined, there are special adhesive tapes that are used to do this.

First ensure that both pieces to be joined will meet together without a crack or bump at or near the crease. Then roll them up and place the adhesive tape on the surface. Apply adhesive to one half at a time. It is critical that the joint is seamless and perfect.

And that’s it. The main work is in the base prep, ensuring that it is flat and compacted and at the correct depth. Beyond that it’s fairly straight forward.

If you want it professionally done, feel free to contact us for a quick estimate!